The maritime and aerospace industries have long sought innovative ways to reduce drag and improve efficiency in fluid dynamics applications. One of the most promising breakthroughs in recent years draws inspiration from an unlikely source: the skin of sharks. Engineers and scientists have turned to the unique texture of shark skin to develop grooved surfaces for turbine blades, propellers, and other hydrodynamic components, leading to significant gains in performance and energy savings.

The Science Behind Shark Skin

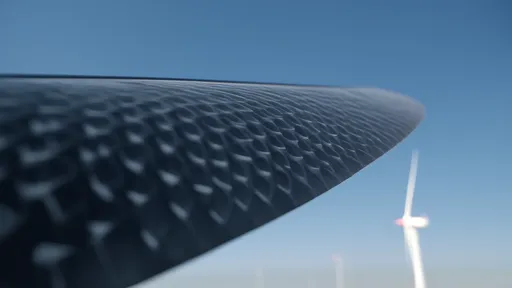

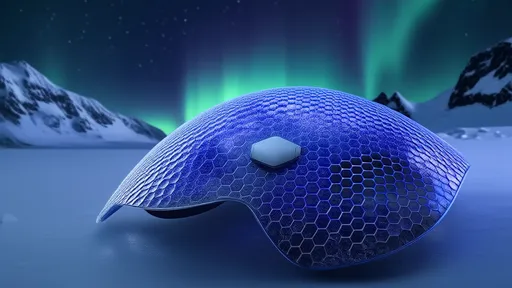

Shark skin is covered with microscopic structures called dermal denticles, which resemble tiny, ridged scales. These denticles are not just protective armor—they play a crucial role in reducing drag as the shark moves through water. The grooves created by these structures disrupt turbulent flow, allowing water to pass over the shark's body with minimal resistance. This natural adaptation has inspired engineers to replicate similar textures on artificial surfaces, particularly in applications where fluid dynamics are critical.

When applied to turbine blades, such as those used in wind or marine energy systems, these grooved surfaces—often referred to as riblets—create a similar effect. By altering the boundary layer of fluid flow, they reduce friction and delay the onset of turbulence. The result is a blade that cuts through air or water more efficiently, requiring less energy to maintain rotation while increasing overall output.

From Nature to Engineering

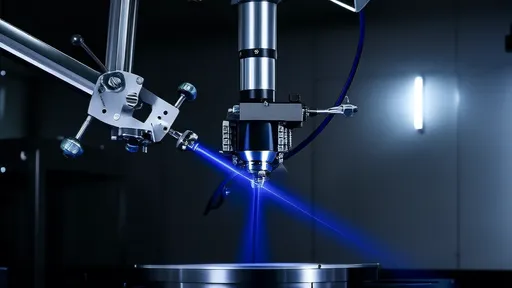

The process of translating shark skin’s properties into functional industrial applications has required extensive research. Early experiments involved testing various groove patterns, depths, and spacings to determine the optimal configuration for drag reduction. Advanced manufacturing techniques, including 3D printing and precision molding, have made it possible to produce these microstructures at scale.

One of the key challenges was ensuring durability. Unlike shark skin, which naturally heals and regenerates, artificial surfaces must withstand harsh environmental conditions, including erosion, corrosion, and mechanical stress. Modern materials such as reinforced polymers and composite coatings have helped overcome these obstacles, making shark-inspired surfaces viable for long-term use in turbines and other high-stress applications.

Real-World Applications and Benefits

The adoption of shark skin-inspired grooves in turbine blades has already shown measurable improvements in efficiency. Wind farms using riblet-treated blades report energy output increases of up to 10%, depending on wind conditions. In marine environments, ships equipped with grooved propeller blades experience reduced fuel consumption due to lower hydrodynamic resistance.

Beyond energy savings, the technology also contributes to sustainability. More efficient turbines mean fewer resources are needed to generate the same amount of power, reducing the carbon footprint of renewable energy systems. Additionally, the extended lifespan of these blades—thanks to reduced wear from drag—translates to less frequent replacements and lower material waste.

Future Prospects and Ongoing Research

While shark skin-inspired grooves have proven effective, researchers continue to explore refinements. Some studies focus on adaptive surfaces that can alter their groove patterns in response to changing flow conditions, mimicking the dynamic flexibility of biological systems. Others investigate hybrid designs that combine riblets with other biomimetic features, such as whale fin tubercles, to further optimize performance.

The potential applications extend beyond turbines. Aircraft wings, HVAC systems, and even sports equipment could benefit from similar drag-reducing technologies. As manufacturing techniques become more precise and cost-effective, the widespread adoption of these bio-inspired designs seems inevitable.

Conclusion

Nature has once again provided a blueprint for solving complex engineering challenges. By studying the microscopic ridges on shark skin, scientists and engineers have unlocked a powerful method for reducing drag and enhancing efficiency in fluid-based systems. The success of grooved turbine blades underscores the value of biomimicry—not just as a novel concept, but as a practical pathway to more sustainable and high-performing technology. As research progresses, the lessons learned from sharks may well ripple across multiple industries, driving innovation for years to come.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025